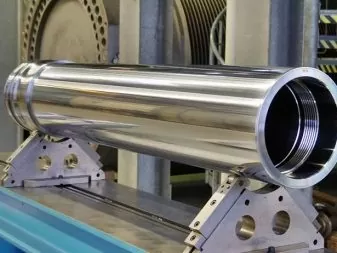

Hard chrome plating

The hard chrome plating process is used in cases where hard surfaces up to 1.2 ∙ 103 MPa (Vickers hardness) are required.

The hard chrome plating process has been used in industry for decades as a replacement for nitriding or surface hardening processes due to the lower process temperature, which results in significantly lower deformations and residual stresses.

Such coatings are characterized by high hardness and favorable sliding properties, as well as corrosion resistance.

Services

- Hard chrome plating

- Zinc phosphating

- Cataphoretic lacquering of elements (KTL)

- Tinn plating

- Brass plating

- Silver plating

- Copper plating

- Trivalent chrome plating of elements (Cr III)

- Decorative chrome plating

- Decorative nickel plating

- Zinc Nickel siling

- Zinc nickel on racks

- Zinc nickel in drums

- Galvanizing elements on racks

- Zinc plating in barrels

Previous